Understanding the Different Types of Automotive Fasteners

While fasteners are used in a variety of industries, automotive fasteners are among the most common. Occupying an approximate 45 percent total market share, automotive fasteners are vital to the safe operation of vehicles. Although fasteners designed specifically for the automotive industry may occupy a large segment of the market, it is important to recognize that there are actually many different types of automotive fasteners, including bolts, screws, nuts, rivets, studs, and more. Each type of fastener functions in the same basic manner, in order to connect or hold to at least two objects together. The way in which they perform that task may vary. It must also be recognized that automotive fasteners may be constructed of various materials, including iron, stainless steel, nickel, brass, and aluminum.

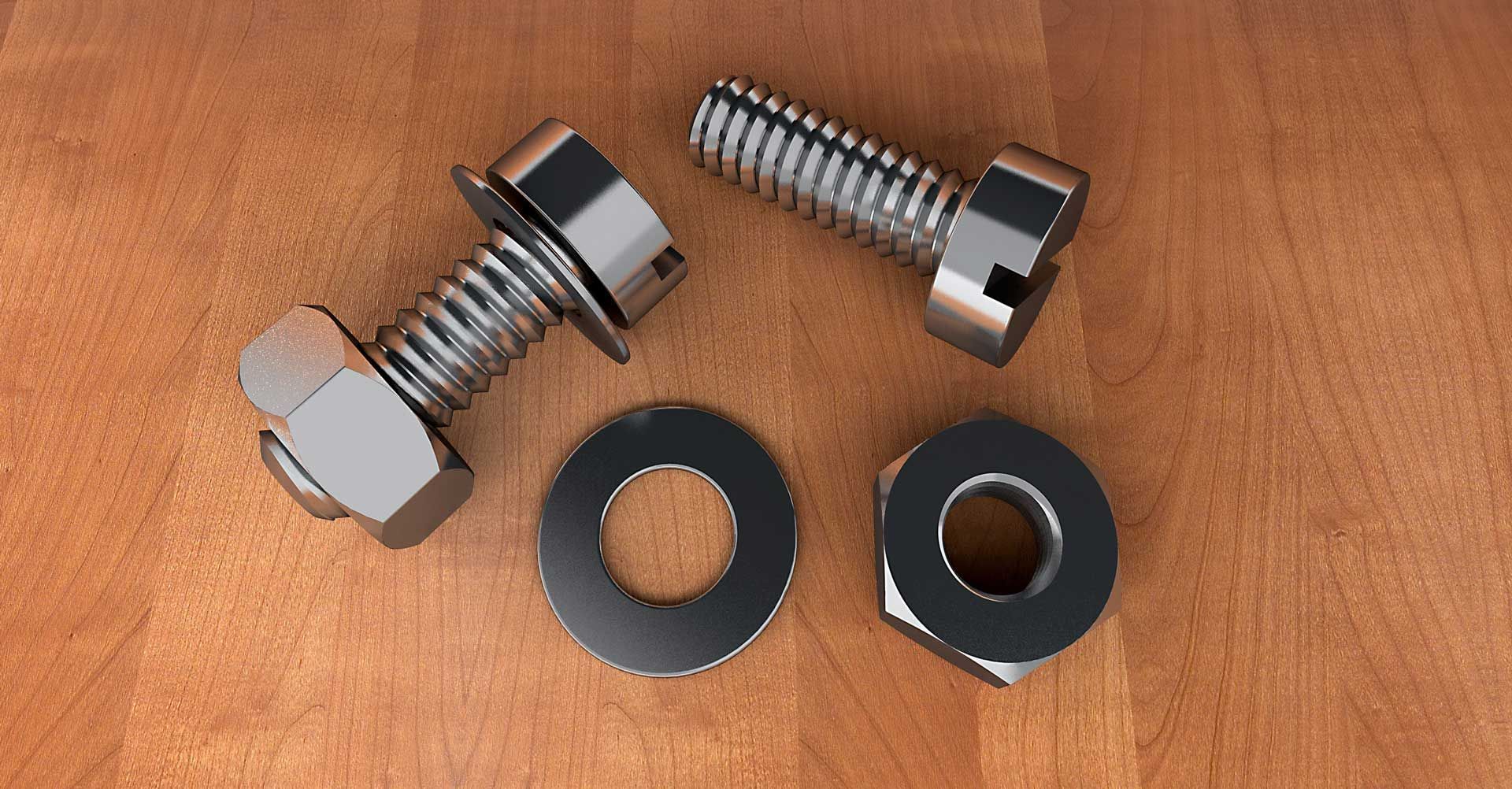

Automotive bolts are often referred to as threaded fasteners. This type of fastener features a head at one end. Such bolts are often inserted through the holes in assembled parts and then fastened using a nut. Various types of automotive bolts include U-bolts, hub bolts, and wheel bolts.

Also important to the industry are automotive nuts. These types of automotive fasteners are typically hexagonal or square in shape and feature a threaded hole that is used in order to screw a bolt that will hold structures together. Auto nuts can be simple in nature or may include t-nuts, collar nuts, locking nuts, lug nuts, jam nuts, hex nuts, or self-locking nuts.

Automotive studs are also commonly used as an automotive fastener. This type of stud is typically fastened at each end with the use of an unthreaded shank. Among the most common types of automotive studs include wheel studs and engine studs. As is the case with other types of automotive fasteners, studs may be constructed of a variety of different materials, including bronze, aluminum, copper, brass, and even nylon and plastic.

In some instances, depending on the nature of pieces that need to be fastened together, automotive washers may also be required. The primary function of a washer is to hold the load of a threaded bolt or fastener. Washers are positioned below the nut in order to distribute pressure. Common types of washers include radiator washer, lug nut washers, and bolt lock washers

Recent Posts

All Rights Reserved | McKellar Machine Products

Proud Members of: