Choosing a Shop to Handle the Production of Custom Fasteners

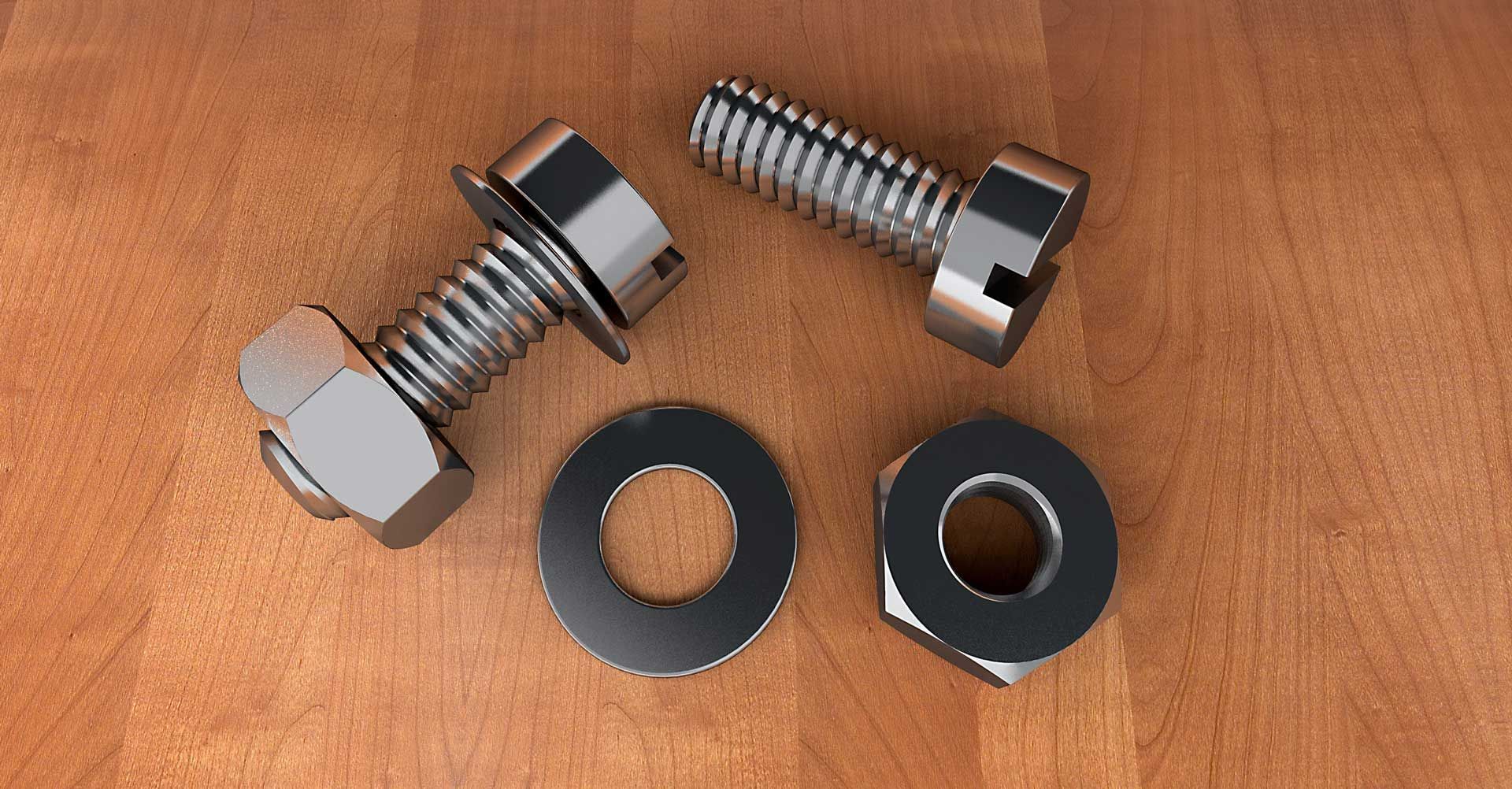

Fasteners that are produced for the specific needs of a client are commonly referred to as custom fasteners. Such fasteners are typically manufactured for factories and other industrial uses. Among the most common situations in which custom fasteners may be required include situations in which the environment is corrosive. This is due to the fact that such custom fasteners can be constructed from metals that are not corrosive in nature.

In producing custom fasteners, it should be understood that various quality standards must be met. This is particularly true in industrial purposes. Custom fasteners are produced by a machine shop using specialized blanks.

As part of the process of selecting a machine shop to handle the production of custom fasteners, it is important to ask several questions in order to ensure that the shop will be able to handle your specific needs. Among the most important questions to ask is the amount of lead-time that the shop requires in order to produce your custom fasteners. Ideally, the shop should offer a short lead-time. Additionally, it is important to determine whether a minimum order applies and if so, the minimum quantity required for an order.

It is also important to determine the various types of custom fasteners that the shop is able to produce. For instance, if you are in need of custom screws, the shop should be able to produce various types of screws, including socket head cap screws, hex head cap screws, flat head, etc. Along with the types of fasteners, it is also vital to determine whether the shop will be able to produce various sizes of screws.

In selecting a shop to handle the production of custom fasteners, consideration should be given to the types of materials to be used. Custom fasteners may be produced from a variety of materials, including stainless steel and aluminum. Additionally, a variety of finishes may be used, such as black zinc, zinc, yellow zinc, nickel, and oxide. In some instances, an anti-vibration material, such as Nylok may need to be added to the fastener, so it is important to ensure that the shop you select is able to handle such additions.

Recent Posts