Tips for Choosing Special Screws

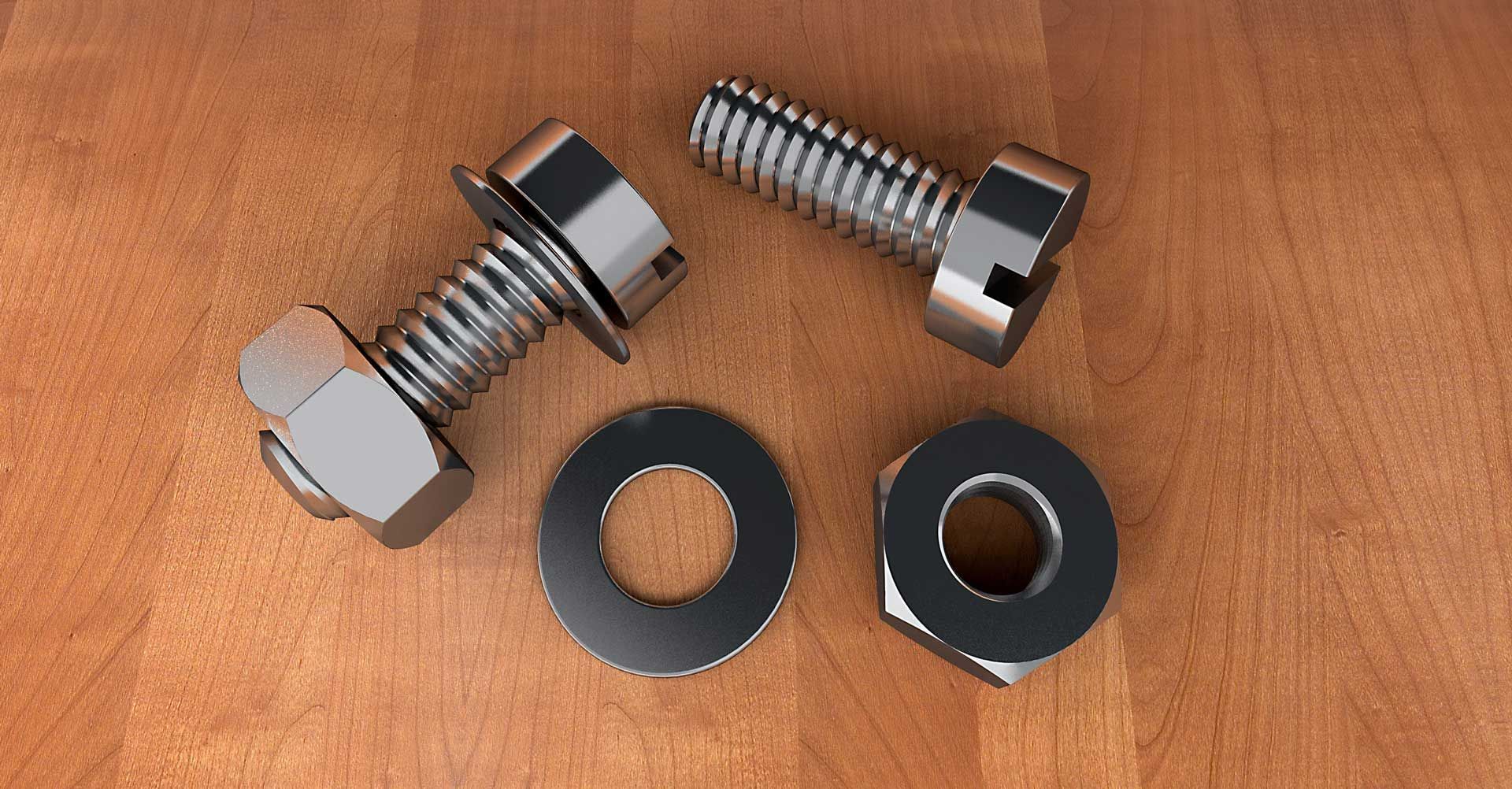

The process of choosing the right screw for a particular application can sometimes be confusing due to the fact that there are so many different types of screws. All screws fall into four basic categories. They are head shape, driving method, material, and thread type. When ordering special screws, these four parameters should be kept in mind.

Driving method refers to the tool and the head type that make it possible for special screws to be secured into the component that needs to be fastened. The most common driving method is slotted, which features a linear slot in the head of the screw, allowing it to be driven with a standard slot screwdriver. Phillips head involves a more aggressive screw type and features an x-shaped groove across the top of the screw head. This makes it possible to drive the screw in a more secure fashion.

In choosing special screws, it must also be kept in mind that there are various head types, including button, pan, truss, oval, flat fillister, and round. The head shape that is selected for a screw will often be based on the specific parameters and requirements of the project.

Thread variety is also important to the selection process of special screws. Screw threads may vary based on counts, thicknesses, and depths. Choice is often based on the relevant use. A wood screw, for instance, will often feature threads that are coarse and deep, whereas a machine screw will feature finer threads that can be gripped by a nut. Sheet metal screws are specifically manufactured to contain coarse threads that make it easier to fasten thin sheets of metal. Self-tapping screws, on the other hand, are designed to create their own holes and are used in softer components, such as wood and plastic. High/low screws may be used when it is necessary for the screw to accommodate alternating height threads.

In choosing special screws, material must also be considered. Such screws can be produced from steel, aluminum, brass, or nylon. The material that is selected to finish the screw must be based on function as well as the need for aesthetics. Depending on the application, a non-stick coating may need to be applied.

Recent Posts